Beautiful Plants For Your Interior

Beautiful Plants For Your Interior

**Upgrading to a Cabinet Table Saw can benefit woodworkers in the following ways:**

- Cabinet saws offer more power and accuracy than contractor saws.

- Cabinet saws typically have better dust collection, resulting in a cleaner and safer work environment.

- Cabinet saws have larger work surfaces and can handle larger pieces of wood.

- Cabinet saws are built to last and require less maintenance than smaller saws.

- Cabinet saws have more safety features, ensuring a safer work environment.

Overall, upgrading to a cabinet saw can improve the quality and efficiency of your woodworking projects, while also increasing safety in the workshop.

**Essential safety features of a table saw** that should be considered include:

* **Blade guards**: A blade guard covers the portion of the blade that's not in use, protecting the operator from accidental contact.

* **Anti-kickback pawls**: The pawls sit on either side of the blade and prevent wood from being kicked back toward the operator.

* **Riving knife**: The riving knife also helps prevent kickback by holding the wood in place as it moves past the blade.

* **Smart sensors**: Some table saws have sensors that detect when fingers come too close to the blade and quickly stop the blade.

* **Overload protection:** This feature will automatically shut off the saw if it overheats or if the motor overloads.

Investing in a table saw with these **essential safety features** will help ensure a safe and efficient woodworking experience.

Regular **table saw maintenance** is crucial to keep the tool safe and functioning properly. This **upkeep** includes cleaning the saw, inspecting parts for damage, adjusting the blade alignment, lubricating moving parts, and replacing worn-out components. Proper **maintenance** ensures the longevity of the saw while preventing accidents and errors.

**Benefits of regular table saw maintenance:**

- Ensures safe operation

- Increases tool lifespan

- Prevents errors and accidents

- Improves precision and accuracy

- Saves time and money on repairs

- Ensures consistent and quality cuts

To build a basic table saw workstation, follow these steps:

- **Materials needed**: 4 pieces of 2x4 wood, 2 pieces of 1x4 wood, screws or nails, glue, measuring tape, saw, sandpaper, drill, and jigsaw.

- **Cut two 2x4 wood pieces to the same length, then attach them perpendicularly using screws or nails.**

- **Repeat step one to make the second frame.**

- **Measure and cut two more 2x4 wood pieces to fit between the frames, then attach them using screws or nails.**

- **Cut the 1x4 wood in half, then attach one piece to each side of the frames, creating the table surface.**

- **Use sandpaper to smooth any rough edges or surfaces.**

- **Drill a hole in the table surface for the saw blade to fit through.**

- **Use a jigsaw to cut a slot on one side of the table surface for the fence to slide in.**

- **Add any additional features, such as a dust collection system.**

With these simple steps, you can easily build a basic table saw workstation using common materials and tools.

Common problems with table saws include blade misalignment, motor issues, and dust buildup. To fix blade misalignment, use a straightedge to adjust the blade angle. For motor issues, check the drive belts and clean debris from the motor housing. Clean dust buildup with compressed air or a vacuum.

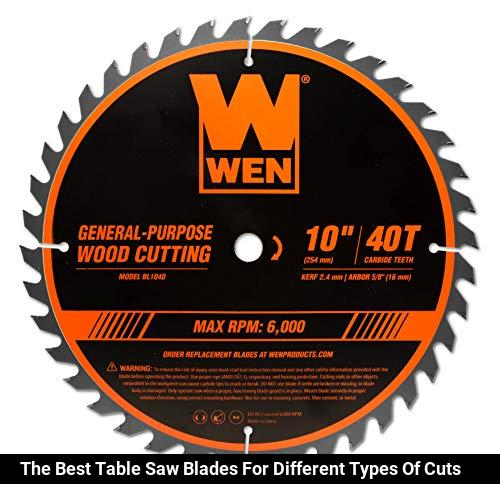

**The Best Table Saw Blades for Different Types of Cuts**:

- Rip Cuts: Use a blade with fewer teeth on it, usually 24 teeth or less. The fewer teeth, the faster the blade will cut through the wood.

- Crosscuts: Use a blade with more teeth, usually 60 teeth or more. The more teeth, the smoother and cleaner the cut will be.

- Dado Cuts: Use a dado blade set that cuts wide slots for joints or grooves in the wood. These blades come in different sizes and are ideal for precision cuts on thicker stock.

In summary, use blades with fewer teeth for rip cuts, more teeth for crosscuts, and dado blade sets for dado cuts.

To use a table saw for accurate rip cuts, follow these steps:

**Step 1:** Ensure that the saw blade is sharp and adequately aligned.

**Step 2:** Adjust the rip fence to the desired width of the cut.

**Step 3:** Use a push stick to guide the wood through the saw blade.

**Step 4:** Maintain a steady pace and keep the wood pressed against the fence.

**Step 5:** Turn off the saw only after the wood has entirely cleared the blade.

By having a sharp blade and adjusting the rip fence to the desired width, you can make accurate and consistent rip cuts using a table saw. Use a push stick to guide the wood and maintain a steady pace to avoid any mistakes.

**Essential Table Saw Accessories for Accurate and Safe Cutting:**

- **Blades:** Choose blades with the right number of teeth for the desired cuts, and make sure they are sharp and in good condition.

- **Fences:** A good fence grips the workpiece tightly and guides it through the blade for straight, accurate cuts.

- **Push sticks or push blocks:** These safety accessories prevent your fingers from getting too close to the blade, while still allowing you to push the workpiece through the cut.

- **Miter gauge:** This tool helps you cut angles accurately and safely by connecting to the saw's tabletop.

- **Riving knife:** This safety feature is a metal plate designed to keep the workpiece from binding against the blade and causing kickback.

- **Dust collection system:** Sawdust can be hazardous to your health and makes a mess in the workshop, so invest in a dust collection system that's compatible with your saw.

These accessories will help any woodworker achieve precise, safe cuts when using their table saw.

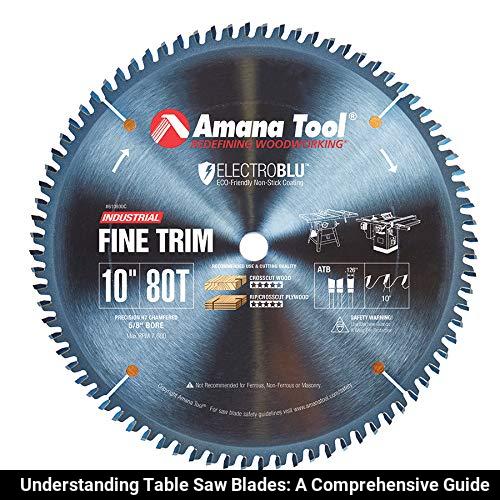

Understanding Table Saw Blades: A Comprehensive Guide

A table saw blade is a crucial component of a table saw that delivers precision, accuracy, and smooth cuts. This guide will help you understand the different types of table saw blades and what they are used for, as well as how to choose the right blade for your specific needs.

Here are the key takeaways from this comprehensive guide on table saw blades:

- There are four primary types of table saw blades: rip blades, crosscut blades, combination blades, and dado blades.

- **Rip blades** are designed for cutting along the grain of the wood, while **crosscut blades** are for cutting across the grain.

- **Combination blades** are versatile and can handle both rip and crosscuts, although they may not produce the smoothest cuts.

- **Dado blades** are used for creating grooves and dados in wood.

- When choosing a blade, consider the size and power of your saw, the thickness and hardness of the materials you will cut, and the type of cut you want to make.

- Blades with more teeth produce smoother cuts, while blades with fewer teeth cut more quickly.

- **Carbide-tipped blades** are more durable and long-lasting than standard steel blades, although they are more expensive.

- It is essential to use the correct blade for the job and ensure that it is properly installed and aligned.

By following these tips, you can choose the right table saw blade for your projects and ensure the best possible results.

Table saws are powerful tools that can cause serious injuries if not used properly. Here are some **tips and tricks** for safe operation:

- **Wear appropriate safety gear** such as eye and ear protection, a dust mask, and non-slip shoes.

- **Inspect the saw** before use to ensure it is in good working condition and that all guards and safety features are in place.

- **Use a push stick or block** to keep your hands away from the blade and maintain a safe distance from the saw.

- **Adjust the blade height** so it does not exceed the thickness of the material being cut.

- **Never reach over the saw blade** or cross your hands in front of the blade.

- **Keep the work area clean and free from clutter** to prevent accidental tripping or slipping.

- **Always turn off the saw** and unplug it before making any adjustments or changing the blade.

Following these **basic safety guidelines** will help ensure safe operation of a table saw and prevent accidents.