Beautiful Plants For Your Interior

Beautiful Plants For Your Interior

Are you tired of using your table saw with worn-out parts? Do you want to save money by repairing it yourself instead of hiring a professional? Look no further, because this DIY guide to replacing worn table saw parts is here to help!

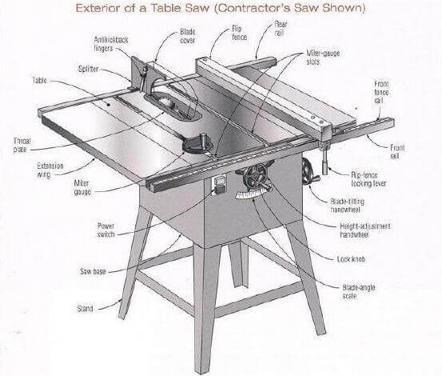

In this article, we will provide you with step-by-step instructions on how to assess your table saw for worn parts and find the replacement parts you need. We will also guide you through the process of removing and replacing the blade, motor, fence assembly, and power switch. And for a smooth cutting experience, we will also teach you how to hone the miter gauge, clean, and lubricate your table saw.

We know that repairing a table saw might seem daunting, but with this DIY guide, you can do it with ease. Think of it as an opportunity to bond with your table saw and gain a better understanding of how it works. So, put on your DIY hat, and let’s get started on replacing those worn table saw parts!

Table saws are an essential tool for woodworking enthusiasts and professionals alike. They make cutting, ripping, and crosscutting wood an easy task. However, with constant use, parts of a table saw can undergo wear and tear, affecting its performance. In such instances, the ideal solution is to replace the worn parts. While this may sound like a task for professionals, you can do it yourself with a little knowledge and the right tools. In this guide, we will cover everything you need to know to replace the worn parts of your table saw. So let’s get started!

Before replacing any parts on your table saw, it is important to assess which parts are causing the issue. One common problem is worn parts. Inspect the blade, arbor, belts, pulleys, and bearings for signs of wear and tear. Check the blade for dullness or wear, and inspect the arbor for any roughness or looseness. Belts or pulleys that are loose or worn can cause problems with the blade’s speed and accuracy. Finally, examine the bearings for any signs of wear or damage.

It is crucial to address worn parts immediately as they can lead to inaccurate cuts or even accidents. Replacing worn parts is an essential part of maintaining your saw’s performance and efficiency over time. So, keep a regular check on the condition of your saw’s parts and don’t hesitate to replace them when necessary.

Once you have identified the parts that need to be replaced, the next step is finding replacement parts. The easiest way to do this is by checking your saw’s manual or manufacturer’s website, which should provide information on the various parts of the saw and their respective part numbers.

If you do not have access to your saw’s manual or the manufacturer’s website, then you can also try looking for replacement parts at local tool or hardware stores. However, it’s important to remember that not all stores may carry the specific part you need, so it’s best to call ahead and inquire about availability before making a trip.

Another option is to search for replacement parts online. There are various websites that specialize in selling replacement parts for power tools like table saws. When ordering online, make sure to provide the correct model number and part number to ensure the part you receive is compatible with your saw.

It’s also worth noting that some replacement parts may be interchangeable between different brands and models of table saws. In such cases, it’s best to consult with a professional or contact the manufacturer for further guidance.

By finding the right replacement parts for your table saw and replacing worn parts in a timely manner, you can not only ensure a smoother and safer operation of your saw, but also prolong its lifespan for years to come.

One of the most common repairs you may need to make to your table saw is replacing the blade. Over time, blades can become dull or damaged and need to be replaced to ensure safe and accurate cuts.

Before you start the process of removing and replacing the blade, ensure that your table saw is unplugged and the power switch is in the off position. If your saw has a lockout tag, use it to prevent someone from accidentally turning on the power while you are working.

Next, raise the blade to its highest position and use a wrench to remove the nut holding the blade in place. Remove the blade guard and lift the blade out of the saw, being careful not to touch the teeth.

When selecting a new blade, ensure that it is compatible with your saw and appropriate for the type of cuts you will be making. Follow the manufacturer’s instructions to correctly install the new blade, being sure to tighten the nut securely.

Remember, improper installation or use of the blade can cause serious injury, so always use caution and follow safety guidelines.

A table saw motor can fail due to wear and tear, or improper use of the saw. Replacing the motor can often be an easy fix for this issue. However, it’s important to ensure that you get the right replacement motor for your table saw. Some motors are universal and fit many different brands, while some are specific to the brand and model of your table saw.

Before starting the replacement process, make sure your table saw is unplugged and all parts are detached from it. Then, remove the motor cover and disconnect the wires from the motor. Carefully remove the motor from its housing by unscrewing it.

Next, install the new motor by carefully reversing the steps you took to remove the old one. Make sure to screw the motor into its housing securely and reconnect the wires.

Once the new motor is installed, turn on the saw to test and ensure it is functioning properly. If you experience any issues or the new motor doesn’t work, it may be best to consult a professional for assistance.

Overall, replacing the motor on your table saw can be a relatively straightforward DIY task, as long as you ensure you have the correct replacement motor and follow the proper steps.

The fence assembly on your table saw is an essential component, as it helps you make precise cuts when ripping or crosscutting lumber. If your fence assembly is worn or damaged, it can affect the quality of your cuts and, in some cases, render your saw unusable. So, it’s essential to replace it promptly if you notice any signs of wear and tear.

To remove your old fence assembly, loosen and remove any screws or bolts holding it in place. Then, slide it out of the channels and cables. When installing the new fence assembly, ensure that it is level with the saw table and tight against the channel walls. To make sure it’s straight, use a straightedge or a square.

Remember to adjust and lock the fence assembly in place before operating your saw. Also, ensure that the fence is parallel to the saw blade and that it does not deflect under pressure.

Replacing your fence assembly can improve your saw’s performance and accuracy when making cuts. So, It’s a repair worth considering, especially if you have an older table saw or use it frequently.

If your table saw doesn’t turn on or may switch on/off without your intention, the power switch may be the culprit. Luckily, replacing it is an easy fix that you can do yourself.

First, unplug the table saw and take off the switch cover. Then, take a picture of the wiring or take note of the wire’s location to help you remember which wire goes where. Disconnect the wires and remove the defective switch.

Check the owner’s manual or search for a replacement switch online that matches your saw’s model number. Some switches may require rewiring or may have different connectors, so pay attention to this before purchasing a new one.

Once you have the new switch, connect the wires and secure the switch in place with screws. Finally, replace the switch cover and test the switch with the saw unplugged before plugging it back in.

By following these simple steps, you can replace your power switch in no time and get back to using your table saw safely and effectively.

The miter gauge of a table saw is an essential component that helps you make perfectly angled cuts with precision. Over time, the miter gauge can become worn and misaligned, resulting in inaccurate cuts, which can be frustrating. However, honing the miter gauge can restore its accuracy and make a significant difference in the quality of your cuts.

To hone the miter gauge, start by cleaning it thoroughly and inspecting it for any visible signs of wear or damage. Next, use a metal file to file any nicks or burrs that may be present on the gauge. This will ensure that the gauge slides smoothly and accurately in its slot.

After filing, check the accuracy of the miter gauge with a square, and make necessary adjustments to achieve perfect 90-degree angles. Finally, lubricate the miter gauge and its slot with a silicone-based lubricant to ensure a smooth gliding motion.

Properly honing your miter gauge can make a huge difference in the precision of your cuts, so don’t overlook this essential step in maintaining your table saw.

Cleaning and lubricating your table saw is crucial to make sure it runs smoothly and lasts longer. This task should be done regularly, and the frequency depends on how often you use your table saw.

Start by cleaning all the sawdust and debris thoroughly from your table saw using a soft brush or vacuum cleaner. Make sure you get into all the nooks and corners of your saw to remove all the sawdust buildup.

Once you’ve cleaned your table saw, it’s essential to lubricate it to prevent rust and reduce friction. Apply a few drops of lubricant to all moving parts like trunnion, gears, pivot points, and other parts that move or rotate.

Make sure you use an appropriate lubricant for your table saw, such as silicone spray or Teflon-based lubricant. Avoid using WD-40 or other penetrating oils as they are not suitable for lubricating your table saw and can damage its components.

Remember to wipe off any excess lubricant and clean any spills to avoid sawdust buildup on the lubricated parts. By keeping your table saw well-lubricated and clean, you’ll not only extend its lifespan, but you’ll also ensure smooth and safe operation.

In the next section, we will share some tips on how to maintain your table saw in good condition.

Proper maintenance of your table saw can improve its lifespan and keep it working at its best. Here are some tips for maintaining your table saw:

By following these simple tips, you can keep your table saw in good condition, improve its performance, and extend its lifespan.

In conclusion, replacing worn parts of your table saw can be easily accomplished with the right tools and some DIY knowledge. Remember to assess your saw for any worn parts and note what needs to be replaced. Finding replacement parts can be done through online retailers or the manufacturer. Replacing the blade, motor or fence assembly will require some dismantling, but with careful precautions, it can be done safely. Replacing the power switch is an easy and affordable fix. Honing the miter gauge is another simple but essential task to ensure accurate cuts. Finally, regular cleaning and lubrication will prolong the life of your table saw. Don’t forget to maintain your saw for optimal performance. With this guide, your table saw will be up and running in no time.