Beautiful Plants For Your Interior

Beautiful Plants For Your Interior

Have you ever struggled with cutting precise curves and circles on your…

Are you looking to take your woodworking skills to the next level?…

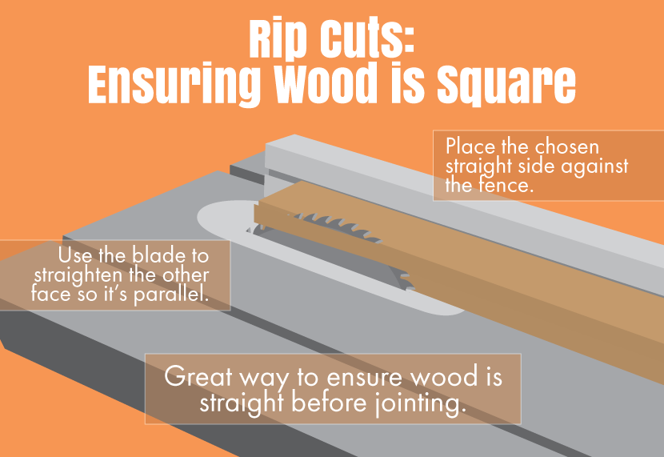

Have you ever found yourself frustrated with the accuracy of your table…

Do you know what separates a basic woodworking project from a professional…

Are you a contractor or a DIY enthusiast who is looking for…

Have you ever tried to cut a large piece of wood, only…

Do you love to work with MDF and Melamine but struggle to…

Have you ever found yourself frustrated with uneven cuts when using a…

Do you know how crucial it is to clean and maintain your…

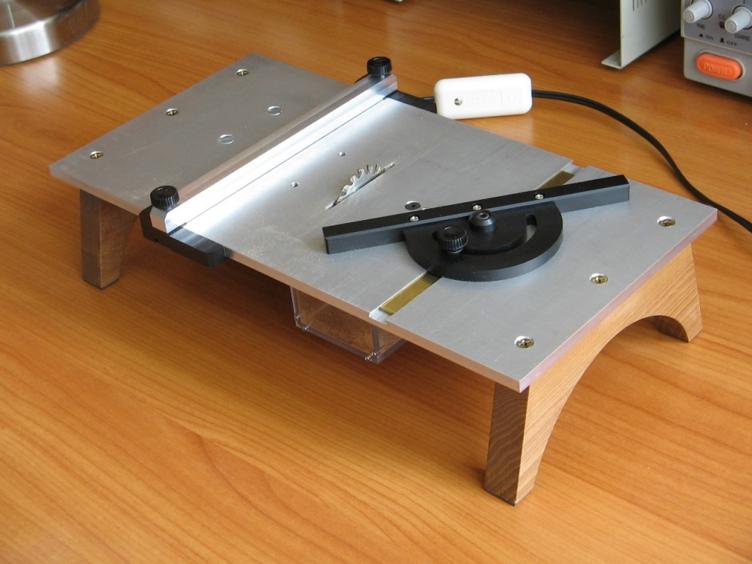

Are you a hobbyist or DIY enthusiast looking for a reliable and…