Beautiful Plants For Your Interior

Beautiful Plants For Your Interior

Are you in the market for a new cabinet table saw but…

Do you love woodworking? Are you in the market for a high-quality,…

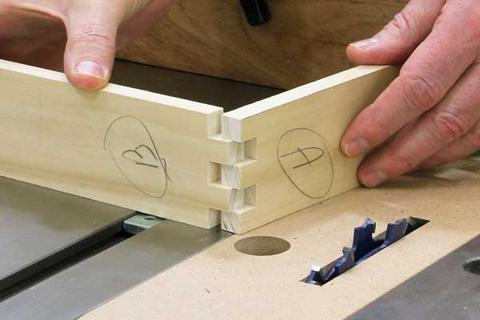

Have you ever wondered how to create those perfectly crafted box joints…

Are you an avid woodworker who’s experienced the heart-stopping moment of table…

Are you tired of using a table saw without the proper tools?…

Are you planning a DIY home improvement project and trying to decide…

Are you considering taking on some renovation projects in your home? If…

Do you have trouble making the perfect bevel cuts for your woodworking…

Are you tired of having to awkwardly balance long pieces of wood…

Are you someone who enjoys working on large woodworking projects but often…