Beautiful Plants For Your Interior

Beautiful Plants For Your Interior

Are you tired of inaccurate cuts on your table saw? Do you…

Are you tired of uneven cuts and inaccurate measurements while woodworking? Do…

Are you a woodworker looking to enhance your table saw’s versatility and…

Are you tired of struggling with a dull table saw blade? It’s…

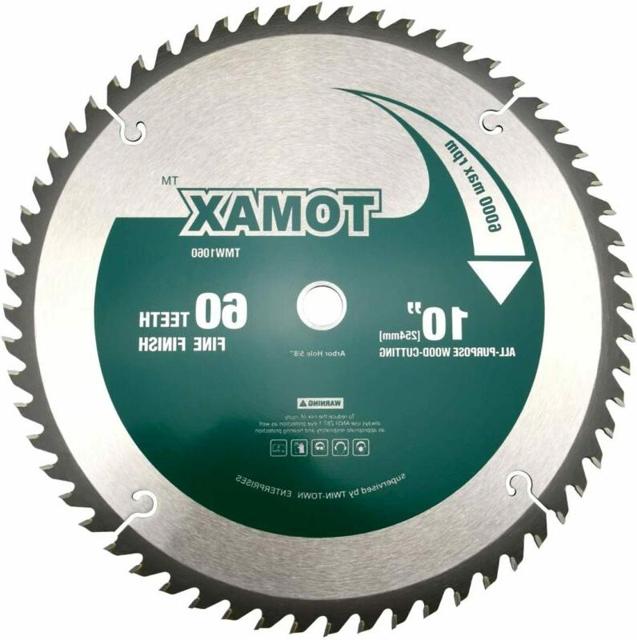

Are you tired of using the wrong table saw blade for your…

Have you ever wondered why safety is such a crucial aspect of…

Are you looking for the ultimate precision cutting tool for your DIY…

Have you ever wished you could take your woodworking projects on the…

Are you tired of having to drag out your bulky table saw…

Have you been debating whether to upgrade your table saw? Are you…